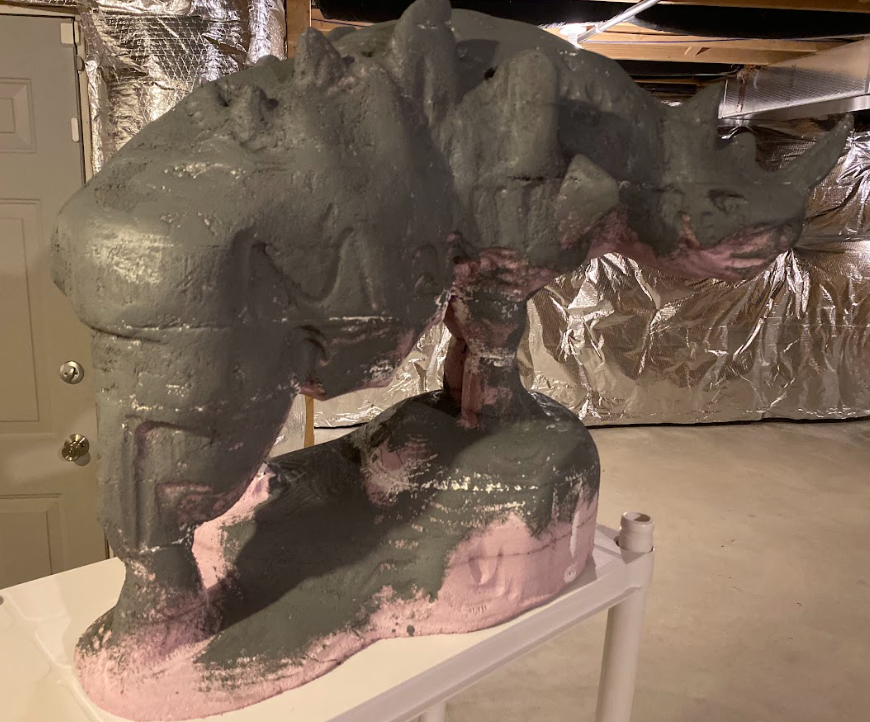

Nathan RJ’s settings and results. A feed rate of 1 inch per second worked well.

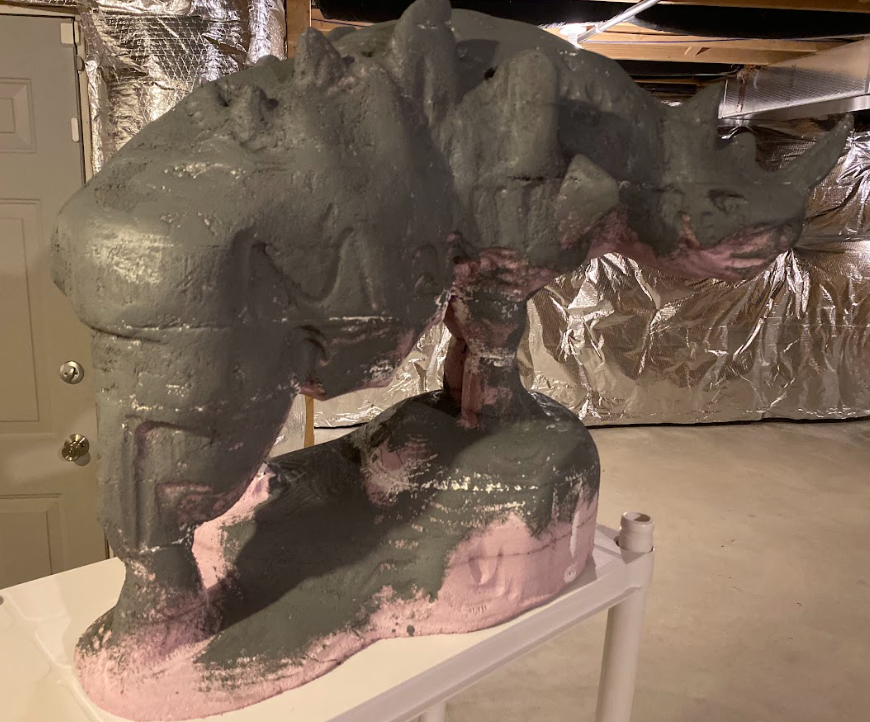

Diego changed the feed rate to 150 inches per minute and it cut just as smoothly and the chips look better:

|

12:11 PM (15 minutes ago) | |||

|

||||

Good Afternoon Joe,

I just talked to Matt, and according to him the answer to your question about locking the B Axes is no, Please try cutting your material at a slower rate, and that should take care of your issue. Please feel free to contact us if you have any further questions.

John

Technical Support

ShopBot Tools, Inc

3333B Industrial Drive, Durham NC 27704

Talk ShopBot Forum (for help and advice on CNC projects) www.TalkShopBot.com/forum