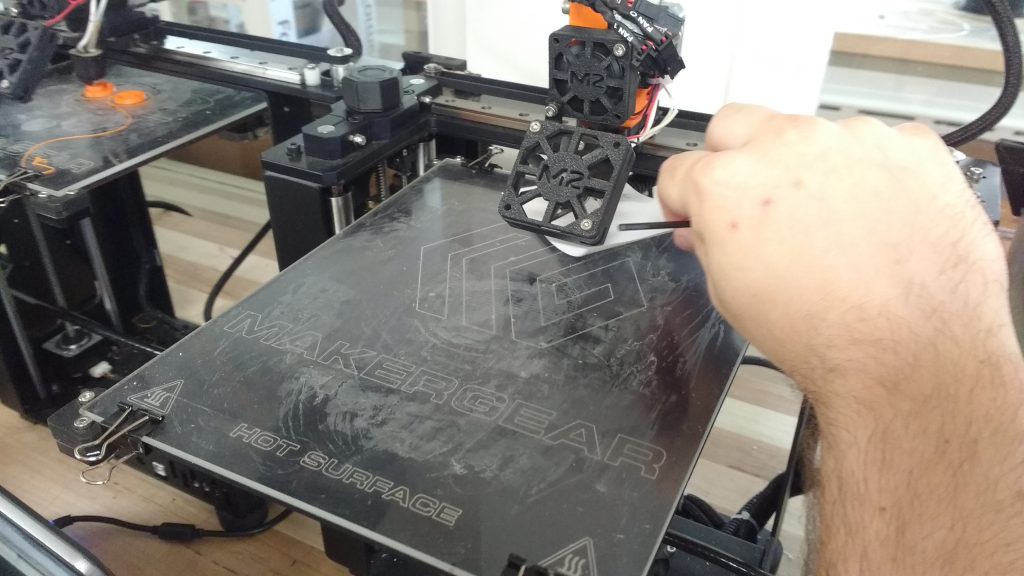

Level the print bed before every job. For best results with the MakerGear and MakerBot printers, level the bed before every job. This will help the filament adhere properly to the bed and distribute evenly. In the image below we see a Student Technician using a sheet of paper to set the correct amount of space between the hotend and print bed.

Note that the leveling procedure is only to be performed by a trained Student Technician because the printer can get damaged if the process is done incorrectly. Ask the Student Technician on duty to help you.

Make sure there’s enough filament on the spool. With small prints and a full spool it’s easy to know that there’s enough filament left, but if you’re printing a larger job you may need to weigh the filament spool to be sure. When you were setting up the toolpath in Simplify 3d, if you made a note of the plastic weight required for your part you can figure out if there’s enough filament on the spool. Here’s how:

- Find a completely full roll of the same filament brand and type (e.g.: Hatchbox ABS) and weigh it.

- Look at the side of the full roll and find the weight of the filament. (usually 1kg)

- Subtract weight 2 from weight 1. This is the weight of the empty spool.

- Now weigh the spool (with filament) from the printer you want to use, and subtract the weight of the spool. This is the weight of the filament left on the spool.

Clean the build plate and add glue before every job. Scrape the build plate with a putty knife to eliminate glue bumps from previous print jobs. Add a fresh coat of glue stick to the build plate to help the first layer of ABS stick during your print job.

Watch the print closely for the first half hour. The first few layers of the print are like the foundation of a house. A bad foundation can cause all sorts of problems with the walls and roof. Watching closely for the first half hour will give you a chance to catch problems early and restart the job if needed.

Is the print bed level? Do the outer walls of the print look like they should? Is the support material building up okay? Are the parts adhering to the build plate? Curling up along the edges (as shown below) can cause a part to deform considerably or fail altogether.

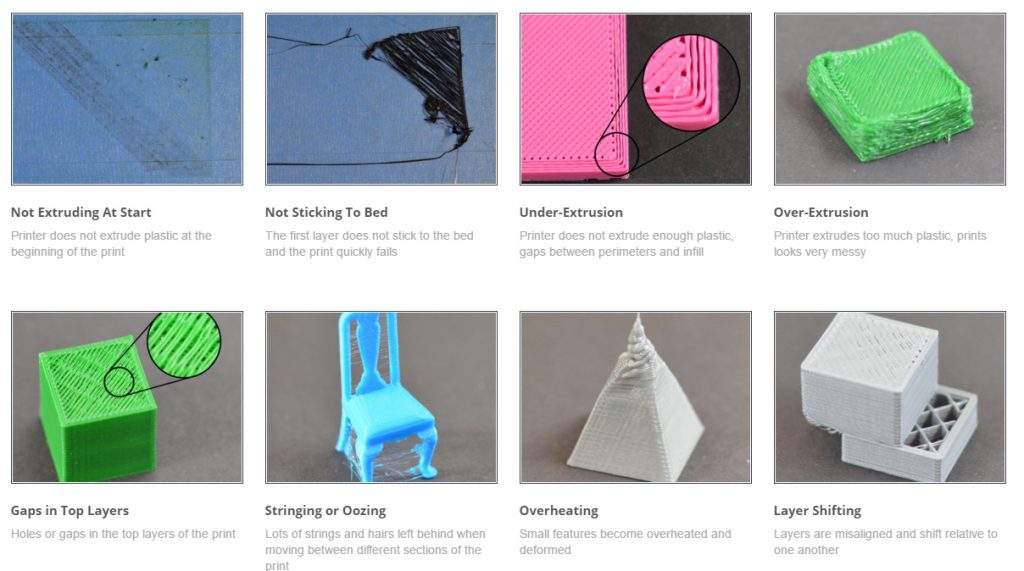

Troubleshoot. Simplify3D has created an excellent troubleshooting guide for 3D printing that you can refer to when you encounter problems. Here’s a link.